Explore Advanced Robotic Actuators - Key Components in Manufacturing Robots KellyOnTech

2023 World Robot Conference

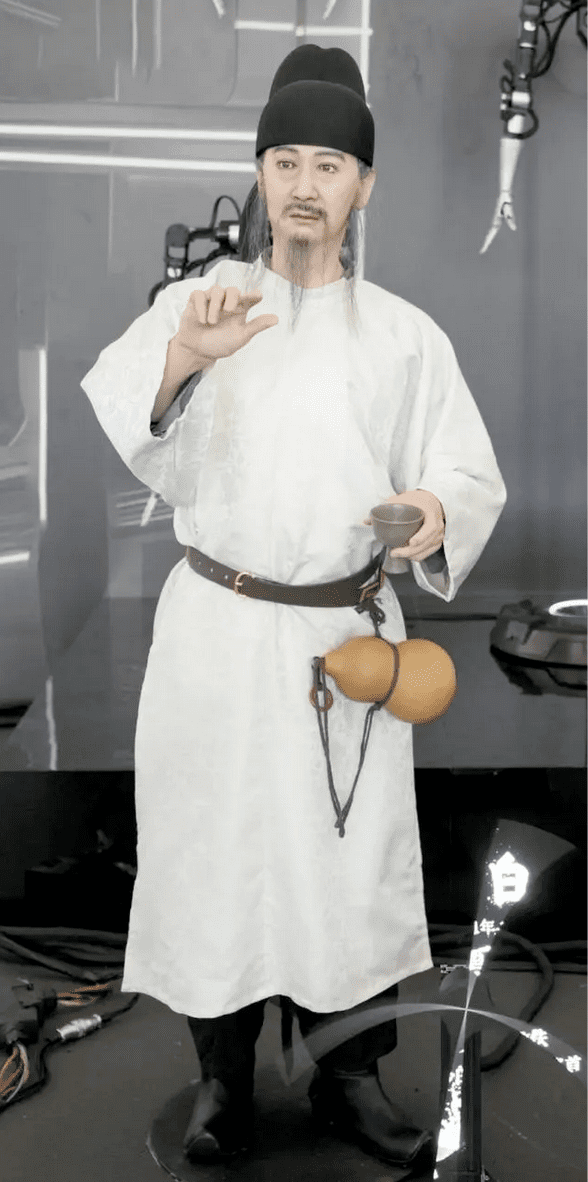

At the 2023 World Robot Conference (Beijing, August 16–22, 2023), organized by the Association for Science and Technology (ASTRA), more than 600 robotic products from 140 companies around the world were displayed. For example, Li Bai, a humanoid robot, is a recreation of the famous poet from 1,300 years ago. And there is also a robot coffee waiter who can make latte art. Which robot impressed you?

On August 16, the Beijing Municipal Bureau of Economy and Information Technology released “Several Measures for Beijing to promote innovation and development of the robot industry, striving to create a source of innovation for robot technology, an application demonstration highland and a high-end industrial cluster. Beijing will set up a 10 billion yuan robotic industry fund, with an initial scale of no less than 2 billion yuan, to support the incubation of innovative teams, the transformation of technological achievements, corporate mergers and acquisitions, .etc. With the support of government policies and the increase in funds, competition among various robotic projects has entered a fierce stage.

Sometimes instead of competing directly in the industry, but provide what the industry needs. This indirect support role can often rise to the top. Just like during the gold rush, Levi Strauss chose to provide durable jeans to gold miners and achieved a great cause.

What is the key to manufacturing robots? Today I will introduce the robot actuator, one of the key components in robot construction.

Robot Actuators — One of the Most Important Components for Building Robots

An actuator is a device that converts energy into physical motion. Most actuators produce rotational or linear motion. Actions that seem simple to humans, such as walking, sitting and lying down, can be challenging for robots, especially humanoid robots. Actuators are needed for robots to move and perform tasks.

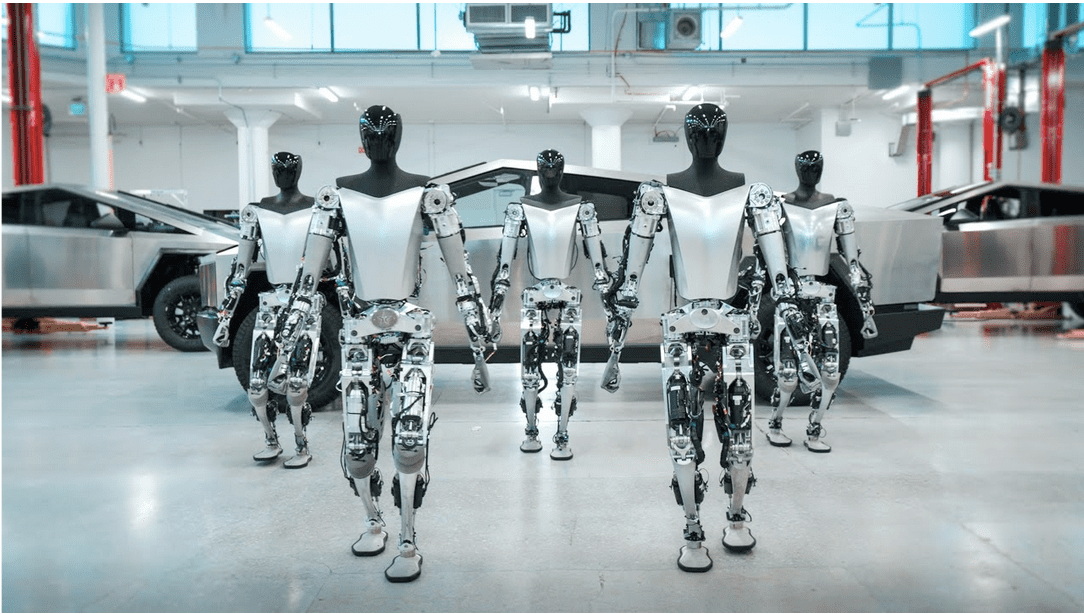

Elon Musk recently mentioned that the main challenge in creating humanoid robots like Tesla Bot lies in the limitation of currently available robot actuators. Robot actuators are also called power batteries for humanoid robots. Take the Tesla Bot as an example. The robot has a maximum speed of 5 mph (8.05 km/h), a standing height of 5 feet 8 inches (173 cm), a weight of 125 pounds (57 kg), and a carrying capability of 45 pounds (20.42 kg). There are 28 body joint actuators, including 14 rotary joints, 14 linear joints and 12 finger joint actuators.

The three most common types of actuators are pneumatic, hydraulic, and electric.

- Pneumatic actuators use compressed air to cause movement.

- Hydraulic actuators use compressed oils to cause movement, they are most commonly used in heavy machinery and can produce very large forces.

- Electric actuators use electric current and magnets to cause movement.

Which type of actuator you choose depends on the type of structure of the robot you are designing.

Why Did Tesla Want to Produce Its Own Robot Actuators?

Tesla did not use conventional robot actuators because according to Elon Musk’s consistent considerations, Tesla robots must be inexpensive. They want this robot to retail at $20,000 per unit, which puts considerable demands on the robot’s light weight, energy-saving, high power density and low power consumption. According to calculations, the Tesla robot requires 23 actuators, a powerful PC, a large number of sensors and battery packs to last more than a few hours, plus a strong skeleton to hold it all together, which is a very difficult task.

So Elon Musk put Konstantinos Laskaris, Tesla’s chief motor designer who he valued highly, in charge of actuator development. Konstantinos has been responsible for the development of motors and actuators for Tesla vehicles for more than a decade. Elon Musk believes that the Tesla electric vehicle itself is a vehicle-shaped robot, so the company has sufficient development experience in robot actuators. At Tesla’s Artificial Intelligence Day 2023, the company unveiled its latest Tesla Optimus Prime prototype, equipped for the first time with Tesla-designed actuators rather than off-the-shelf products.

Tesla once demonstrated the performance of an actuator it developed itself. As shown in the picture, the Tesla actuator lifted a 500 kg piano about 2 inches (5.08 cm) off the ground.

There are many manufacturers that produce robot actuators. Can any company that can make robot actuators that are lightweight, small in size and yet highly efficient? Yes, here I introduce a company called ESTAT.

ESTAT — A New Player in the field of Robot Actuators

ESTAT, a company that started in a Laboratory at Carnegie Mellon University, is dedicated to building robots that help people with limited mobility. Its co-founder Stuart Diller gained a Ph.D. degree in mechanical engineering from Carnegie Mellon University. ESTAT realized that for robots to be useful in real-world environments, the hardware would have to become lighter, more efficient, and more scalable. So they combined their expertise in electrostatic physics with world-class advances in mechanical design and material science to create best-in-class electronic adhesive hardware.

On their website, ESTAT claims their hardware:

- 10 times lighter — the lightest design on the market, using paper-thin composites and high-performance materials

- 10 times more compact — Electroadhesion eliminates the need for bulky components such as electromagnets.

- 1000 times more efficient — ESTAT products act like load-carrying capacitors, requiring only millijoules of energy to activate and microamps of current to maintain.

According to Elon Musk’s optimistic prediction, “In the future everyone will own a humanoid robot, and this market will exceed the demand for electric vehicles.” According to Goldman Sachs, under ideal conditions where the technology achieves revolutionary breakthroughs, the compound annual growth rate (CAGR) of humanoid robots can reach 94% from 2025 to 2035. In 2035, the market size will reach $154 billion. In fact, no matter what form robots exist in, they have already penetrated into all aspects of our lives.